Some slab panels of a residential building were observed to suffer from cracks ranging from 0.9mm to 3.0mm, at Level 2, Level 3 and Level 4. Depth of cracks measured were close to 140mm.

OUR SERVICES

Take Look Into Our Best Services

Project Title

Nature of Problem

Rectification of dry cracks was carried out by cleaning out the cracks, and flooding the crack with Roadware 10 Minutes Concrete Mender. The material self-injects into the crack and silica sand is added occasionally to the surface and the excess material is wiped away with a trowel. The repaired area was fully trafficable after 10 minutes and a grinding stone was used to match the repaired area with its surroundings.

Project Title

Nature of Problem

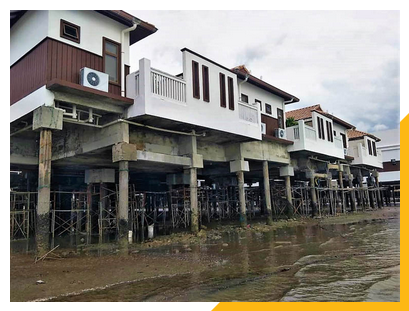

Spalling concrete and deteriorated existing reinforcement bar were observed at splash zone of pier feet where subjected to cyclic wet and dry environment. Over the years, the piers were observed with substantial section loss well before design life due to marine environment exposure requiring immediate strengthening and remediation works.

The Solution

Pier protection was carried out to the affected pers by removing damaged concrete and reinforcement bars, and reinstate by means of pier enlargement using Self – Compacting Remediation Concrete (SCRC). The remediation works included installation of sacrificial anodes (CorrPre Anodes) and protective coating using polymer modified cementitious coating, Flexcrete Cemprotec E942.

Project Title

Nature of Problem

Strengthening to the existing main beam, secondary beams and slabs were required due to loss of strength after fire in the CCB UPS Battery Room.

The Solution

Rectification and reinstatement works involved formwork grouting using shrinkage compensated cementitious grout to recast the slab opening. New opening involved controlled demolition and opening works including diamond cutting and coring in the reinforced slab to the required size of opening.

Structural strengthening to the new opening for the reinforced staircase construction was carried out by installing universal I beams.

New Crack Repair Technology – Roadware

- High-penetration two-part hybrid urethane that combines with manufactured sand to form a tough instant polymer concrete.

- Extremely low viscosity and properties that allow deep penetration into concrete.

Benefits of Roadware 10 Minute Concrete Mender

Project Profile

Project Title

Nature of Problem

Fire had seriously damaged the underside structures at one apartment unit on Level 7 at Tanjung Tuan Resort, Port Dickson.

The Solution

RNC Technology (M) Sdn Bhd was engaged to carry on the condition assessment and concrete testing work to the damages structures. Test report had shown that the in-situ concrete strength is below the allowable grade.

Strengthening was carried out to the affected beams using CFRP and to the affected slab by thickening the soffit of slab. Remedial works such as patching and crack repair were also carried out to the defective areas.

Project Title

Nature of Problem

In order to determine the condition of existing 52 numbers of timber piles, underwater inspection was proposed to be conducted to determine the extent of defects and their dimensions.

The Solution

Underwater inspection to selected timber piles included cleaning of marine growth from under deck to seabed, swim by for overall condition survey including determination of decay and any anomalies present in the piles. The depth of piles was measured using a measuring tape from underdeck to seabed level. Observations and findings were recorded.